A word that always makes the hair on the back of my neck stand up is “shrink.” Also known as food waste, shrink is the left over, unsellable perishable merchandise that every retailer hates to see collecting in the backroom.

Shrink has many root causes, including aged perishable product inventory and even general product mishandling. It is almost always a total loss of profit and sales, creating a negative impact on your financials.

So, how is it possible to generate positive shrink? (A technique also known as making lemonade out of ripe lemons). Take a quick look below on how to repurpose your potential shrink into salvaged profits and sales!

Sharing positive shrink with other perishable departments

The normal process of culling the produce department often throughout the day generates an abundance of items that are not fit for being on the sales floor. Many of these culled items are pulled from the sales shelf due to minor cosmetic blemishes that I like to call “scratch and dents.”

Think about a crisp red bell pepper that was at the bottom of the pile and now has a slight crack on one side. These are the types of culled items that have potential to become something more than compost at the local landfill.

Many retail organizations have programs set up to help repurpose potential shrink loss items, like the cracked red bell pepper example. These repurpose programs are not exclusive to the produce department; they involve all perishable departments within the store.

The meat, seafood, deli, bakery and even juice bar departments all have many uses for the slightly blemished culls identified in the produce department. It is important to share the opportunity of repurposing multiple items with the folks from other departments inside the four walls of the store. Items that do not have a repurpose plan in the produce department might be eligible for an alternative repurpose plan somewhere else within the store.

Strong communication among department managers and the overall understanding of how to effectively repurpose potential shrink will pay dividends to the total store profit & loss report!

Identifying “scratch and dent” fruit and veggies that can be repurposed

Every perishable department within the store should have a list of fruit and veggie items used for further processing into different finished products. Some produce departments have the luxury of operating their own in-store cut fruit/cut vegetable processing program. This allows them to use a tremendous amount of the culled “scratch and dent” items not fit for the shelf.

Items such as melons, pineapple, peppers, onions, and even soft squash are used within processing programs to create items like ready-to-eat fruit cups, ready-to-cook kabobs, fajita mix, and even packages of cut grilling veggies.

The deli department at your store might be the central headquarters for everything processed. In this case, the deli is equipped with team members, packaging, and a facility that allows them to further process many different items. This includes processing ingredients for packaged salads or bulk salad bars.

With that said, “scratch and dent” items like cucumbers, bell peppers, broccoli and cauliflower are all great for being repurposed. Deli departments that host scratch cooking for prepared meals can also repurpose and use cooking items like onions, potatoes and tomatoes. What other “scratch and dent” fruit and veggies items can your deli put to good use?

The bakery department is limited to the variety of “scratch and dent” fruits and veggies that they can repurpose. At the top of my list of items to repurpose is bananas. I have seen many retailers that pride themselves on signature items like fresh baked banana nut bread and banana nut muffins.

If communication between the produce and bakery teams remains high, the “scratch and dent” or overripe bananas used in these signature item recipes will become positive shrink, netting the bakery a lower cost of goods and a higher overall profit dollar. What other fruit and veggie items can your bakery repurpose?

The meat and seafood departments have an arsenal of prepared items that require several different fresh-cut veggies. One of their most popular prepared items, fresh kabobs, happens to include bell peppers and onions. Knowing this, whenever the produce team culls some “scratch and dent” bell peppers or onions, they should be offered to the meat department instead of the trash dumpster.

Packaged fajita mixes, stew mixes and kabobs are all great examples of further processed “scratch and dent” items in the meat department that can help generate positive shrink by reducing the cost of goods and improving profit dollars. What other fruits or veggies can your meat and seafood department repurpose?

The department that can use the most amounts of culled fruits and veggies from the produce department happens to be an instore juice bar. Melons, pineapple, citrus, apples, bananas, cucumbers, celery, carrots, beets and even fresh herbs are all common ingredients that many juice bars use every day.

These items, when culled from produce shelves as “scratch and dent,” should always be offered to the juice bar for further processing versus clogging up the backroom dumpster. The juicing process does not care about cosmetic imperfections, bumps, or bruises! What other fruits and veggies can your juice bar put to good use?

Next steps in sharing positive shrink benefits

Do not throw away any of the "re-purpose" items before offering them to all perishable departments!

A produce team checklist

- Step 1: Working with all perishable departments, establish a list of repurpose items needed by each department.

- Step 2: Cull the produce department first thing every morning. Intentionally box up culled items from the repurpose list that are “scratch and dent” quality — slightly blemished, but still wholesome. Example: Save a box of blemished bell pepper and onion culls for the meat department to use in kabobs.

- Step 3: Set aside all culled items that can and will be repurposed by the produce team. Examples: Melons for using in fruit cups, pineapples for coring, and zucchini squash for grilled veggie trays.

- Step 4: Call the other departments on the store intercom to let them know what repurpose item are available or stop by their department with some of the culled repurpose items from the list. Make sure that your loss from “scratch and dent” fruit and veggie culls becomes a gift for other departments in your store. The total store profit & loss statement will thank you!

- Step 5: Cull the department throughout the day, collecting re-purpose items for all departments. Repeat steps 1-4 throughout the day and night.

Never throw away a potential re-purpose item that other departments within your store can use!

Turn potential negative food waste loss into positive dollars!

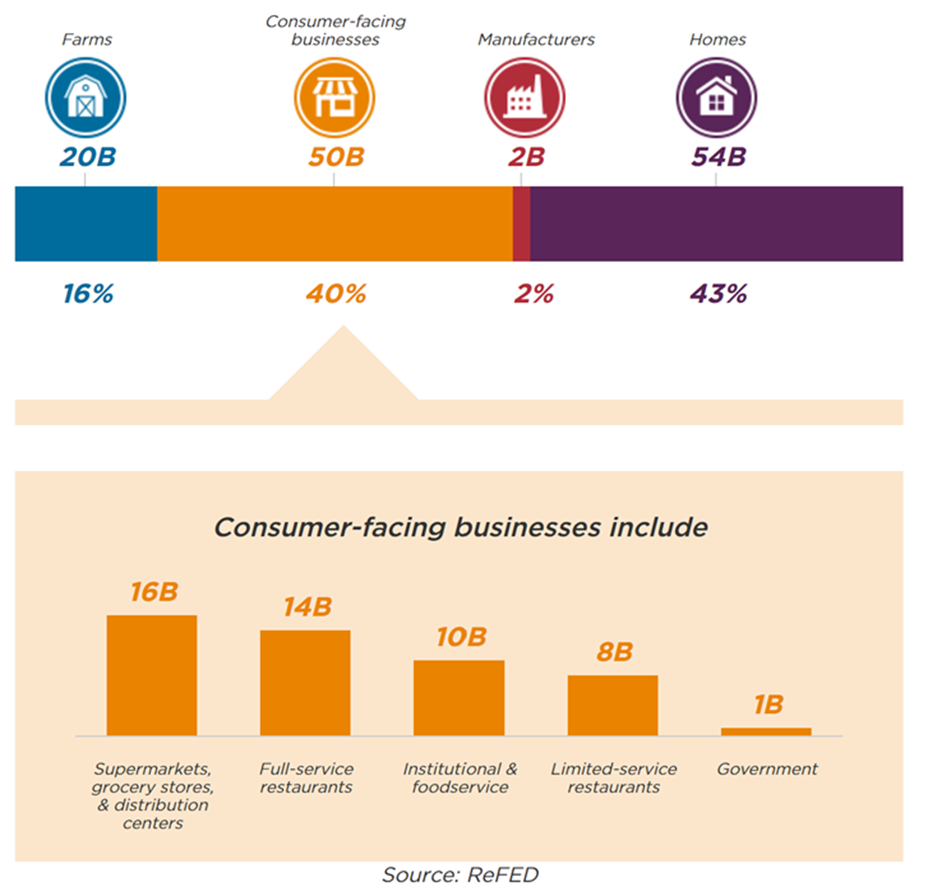

Recent data from Feeding America shows that 108 billion pounds of food is wasted in the U.S. each year. That equates to more than $161 billion worth of food thrown away each year.

Shockingly, nearly 40% of all food in America is wasted and never consumed. Retailers play a huge part in food waste that creates these multibillion-dollar losses. Based on the data below from Feeding America, $16 billion in food waste loss comes from “supermarkets, grocery stores, and distribution centers.”

Retail organizations like yours have an opportunity to reduce the amount of our nation's food waste and strengthen your bottom-line profits simultaneously. What is your organization doing to recover some of that $16 billion?

Scott Schuette is a produce retail veteran of more than 35 years and was most recently the vice president of produce and floral for Fresh Thyme Market. He has been named Produce Retailer of the Year and Specialty Food Retailer of the Year over the course of his decades of service to the fresh produce industry.