Is your store ready for the hottest part of this summer? Maybe not! A broken cold chain can cost a retailer a small fortune between food waste and a huge decline in repeat customer traffic. I highly recommend taking time out now – yes, now! – to ensure cold-chain compliance, especially in my favorite department, produce.

It only takes a quick, systematic inspection of your department to expose any issues. The following 3-step inspection will also ensure your customers are receiving the freshest product possible, with longest shelf-life and best overall eating experience.

The produce manager should have 100% ownership of verifying the cold chain throughout the day, and assistant produce managers and night supervisor clerk positions need to carry the torch when the produce manager is off duty.

Having three sets of eyes on the cold chain all week long is a must.

Remember, something as simple as a packaged salad display case running at 48 degrees Fahrenheit instead of 38 will shorten shelf-life by several days and increase food waste shrink loss substantially. Check your cold chain and keep your cool!

Display case temperature verification

Your hard work merchandising the department for freshness, sales and profit will be wasted if you do not make sure the refrigerated display cases are operating in the proper temperature range. Check throughout the day to make sure all refrigerated display cases are running within the recommended temperature range, usually 36-38 degrees.

Wet rack cases, multi-deck style cases, refrigerated tables, refrigerated endcaps and refrigerated satellite display cases all need temperature verification by using a well-calibrated infrared or digital probe-style thermometer. Even refrigerated display cases that operate with remote temperature warning sensors need inspection. Appropriate display case temperatures will greatly reduce shrink and extend product shelf-life.

If you're conducting your inspection and find an issue, it needs to be reported to store management immediately.

Every retailer should have a repair and maintenance protocol to follow when refrigerated equipment is not performing. Such issues usually require the help of professional refrigeration technicians.

If encounter a warm display case, items for which higher temperatures present food safety concerns should be immediately removed until repairs can be made. Items like fresh-squeezed juice, packaged salads, refrigerated dips and dressings, and value-added cut fruit and vegetables are examples of such categories.

Backroom storage cooler temperature verification

The optimum backroom storage cooler temperature throughout business hours is 37-40 degrees Fahrenheit. When the store is closed, a backroom storage cooler temperature of 35-36 degrees Fahrenheit is sufficient.

Keep the cooler door closed as much as possible all day long. Replace any broken or missing cooler door cold chain flaps, replace burnt out condenser fans, and turn the lights off when not in use.

Make sure that the most perishable items in the cooler – items like berries, cherries, mushrooms, grapes and fresh-cut value-added products – are all stored in the coldest section of the backroom cooler. Avoid storing these items closest to the cooler door.

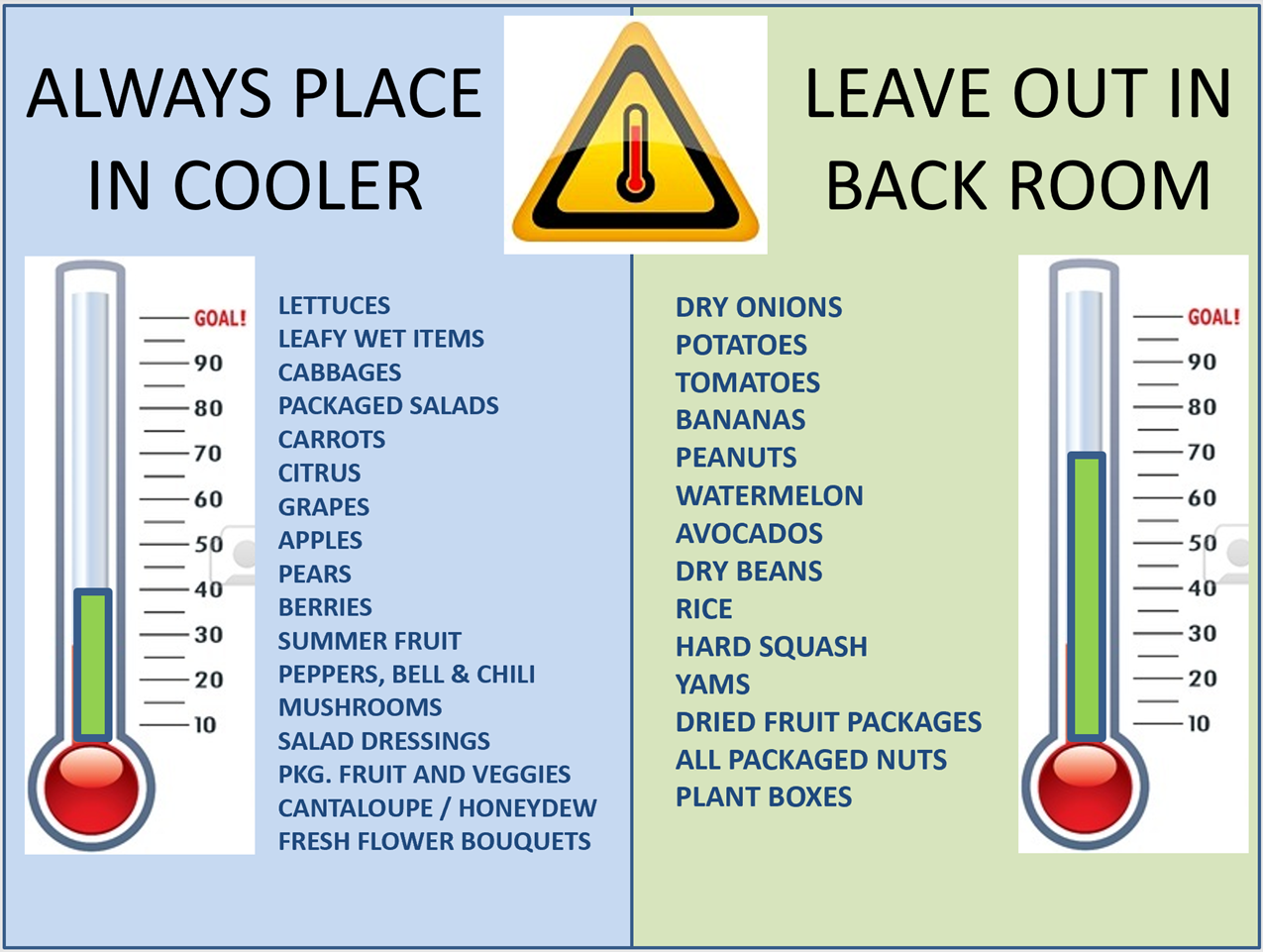

Finally, always make sure that the right items are being stored inside the backroom storage cooler. See chart below for a quick example of categories that need refrigeration versus products that should be stored in other ambient temperature areas.

Product temperature verification at point of receiving

All product deliveries need to be received with a “truck-to-cooler” mentality. Never leave newly delivered product sitting out of refrigeration in the backroom or on the receiving dock. Always have your backroom produce cooler clean, organized and ready to receive new product prior to the delivery truck arriving.

Do not open the delivery trailer doors until the driver and receiver are ready to start the unloading process. Keeping the delivery truck doors closed keeps heat and humidity out and cold air in.

If you suspect any temperature issue at the point of receiving – warm temperatures inside the delivery trailer or visible freeze damage on product – perform the following steps immediately upon unloading.

1. Use a digital probe thermometer to obtain a true reading of perishable product core pulp temperatures. The probe thermometer must be calibrated daily.

2. Calibrating your probe thermometer is simple. Follow these easy steps to properly calibrate your thermometer using the “cold calibration” method.

- Mix equal parts of crushed iced and cold water in a container.

- Stir the water and let it sit long enough for the heat to distribute evenly (usually around 3 minutes).

- Insert the probe thermometer into the container, taking care not to touch the sides.

- Check that the temperature is 30-34 degrees Fahrenheit.

- If the temperature is not within that range, adjust your thermometer to the correct temperature while it is still in the water.

3. Conduct random pulp temperature checks on key perishable items throughout the delivery. The temperature test should be completed on the delivery trailer or immediately after the product is removed from the delivery truck. It is imperative to get an accurate internal pulp temperature of the product and not the outside packaging temperature of products. (See below)

4. If any pulp temperatures on highly perishable items are found to be higher than 41 degrees Fahrenheit or below 32 degrees Fahrenheit, quarantine them immediately and prepare them for a second temperature check. Items that are deemed out of proper food safety temperature range will need proper documentation, supplier notification and agreed-upon disposal. Never attempt to sell highly perishable product that arrives with food safety temperature concerns.

Although many backdoor receivers check the temperatures of perishable, dairy and frozen items, teamwork between the produce folks and the backdoor receiver is essential. Trained produce team members need to assist in selecting the highly perishable items and pulp testing them for cold chain adherence.

It is the produce team that is also responsible for reporting any product received out of the food safety temperature zone and segregating these items from inventory.

Cold chain checklist

Every year, July and August present extreme hot weather challenges. These warmer outside temperatures have the potential to negatively influence the cold chain temperatures inside every retail building. Warmer product temperatures within a brick-and-mortar store end up causing premature ripening, product decay and breakdown, diminished shelf-life and plenty of disappointed customers.

- Maximize your profits – and your product integrity – by making sure refrigerated display equipment is operating perfectly throughout the entire day, seven days a week.

- Treat your backroom storage cooler like your personal refrigerator at home. Keep the door closed at all times and system operating at a temperature within the proper zone.

- Make sure that all product deliveries at the back door arrive within food safety temperature ranges. Inspect what you expect for product temperatures at the point of receiving.

Lessen food waste, improve profits, and build customer loyalty with a strong cold chain!

Scott Schuette is a produce retail veteran of more than 35 years and was most recently the vice president of produce and floral for Fresh Thyme Market. He has been named Produce Retailer of the Year and Specialty Food Retailer of the Year over the course of his decades of service to the fresh produce industry.