Photos courtesy Scott Schuette and Chiquita Fresh North America

As I walked several stores this week, it was easy to see that bananas are taking a back seat at many retailers this summer. Certainly, it can be hard to remember the importance of the banana category when sweet, juicy cherries, peaches and melons start stealing the spotlight.

Truth be told, bananas are still the highest tonnage item in most produce departments during the summer months and throughout the year. For that reason, proper care of the category at the store level should always be a high priority.

In fact, because the summer brings higher temperatures, it is imperative to actually increase the care and handling efforts of this fragile fruit even as all the seasonal items are rolling in alongside them.

I was fortunate to work with some incredible wholesale banana experts during my career. My biggest banana care and handling mentor is Ron Jackson, director of sales for Chiquita Fresh North America. The passion, knowledge and helpful tips that Ron provided me over a decade ago still resonate loudly in my ears every time I visit a grocery store.

My favorite of Ron's was this: “Treat every bunch of bananas like a carton of fresh eggs.” He is right; bananas are extremely fragile and need our year-round attention to ensure that the end user, your customer, has the best possible eating experience.

Here are some important everyday considerations to give bananas this summer and throughout the year.

Receiving best practices

Once your store-level banana delivery is unloaded from the truck, move the pallet to an ambient location with optimum temperatures between 56-68 degrees. Separate the banana cases from other items that might be commingled together on the delivery pallet. Colder items like grapes or berries mixed with bananas on the same pallet can cause cold chain issues and chill damage to the bananas.

When truck-to-shelf receiving of bananas is not possible, make sure that a truck-to-staging area mentality is always in place.

Remove any shroud/bag covering from the delivery pallet immediately to avoid an accelerated increase in banana temperature. Increasing the internal pulp temperature of bananas causes quicker ripening and shorter shelf-life at both store level and the customer's kitchen counter.

When receiving bananas, be sure to keep the product away from refrigeration to avoid chill induced damage to the fruit. Never stage inbound banana shipments in a refrigerated cooler, next to a freezer or cooler door with cold air drafts, or next to other cold temperature products.

Also be sure that high heat sources and warmer storage areas are not used for banana staging or storage. Hot temperatures from backroom equipment and open receiving dock doors can accelerate banana pulp temperatures and ripening very quickly.

Staging arrivals and backstock

There is nothing worse than walking into a store and seeing bananas stacked on a pallet from the day before, still wrapped in a plastic shroud, and not ventilated. The smell of internally cooking bananas is evident, as is the ripe color 6 stage of product that has been neglected.

Uncapping and air-stacking inbound banana cases should occur immediately after receiving the product, not the next day. The process is very simple and outlined below:

- Remove the box lid and place the full box of bananas back inside the lid.

- Pull the plastic over the box so that bananas receive maximum airflow ventilation.

- Cross-stack the bananas to allow proper air circulation.

- Handle the boxes gently. Bruising can occur easily if they're mishandled or dropped.

- Keep product away from heat vents or cold drafts. Temperatures below 55 degrees can cause bananas to turn gray, and temperatures above 68 degrees can cause bananas to ripen prematurely.

Reminder: If uncapping and air stacking back stock is not occurring, it may lead to high pulp temperatures, a decrease in shelf life, and ultimately, excessive shrink loss.

Merchandising

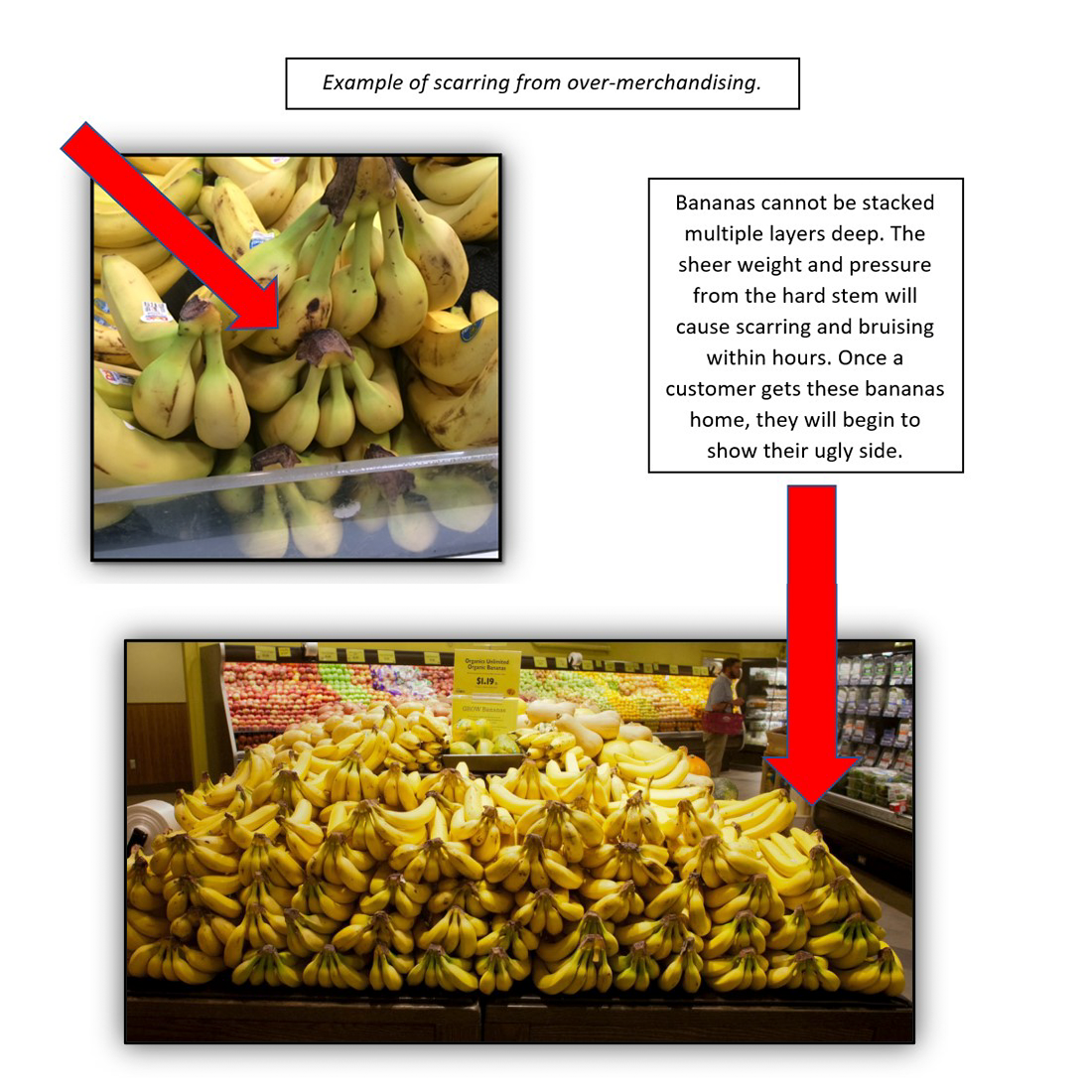

If I had a nickel for every time that I walked into a store and saw bananas displayed three or more layers deep, I would not need a 401k plan.

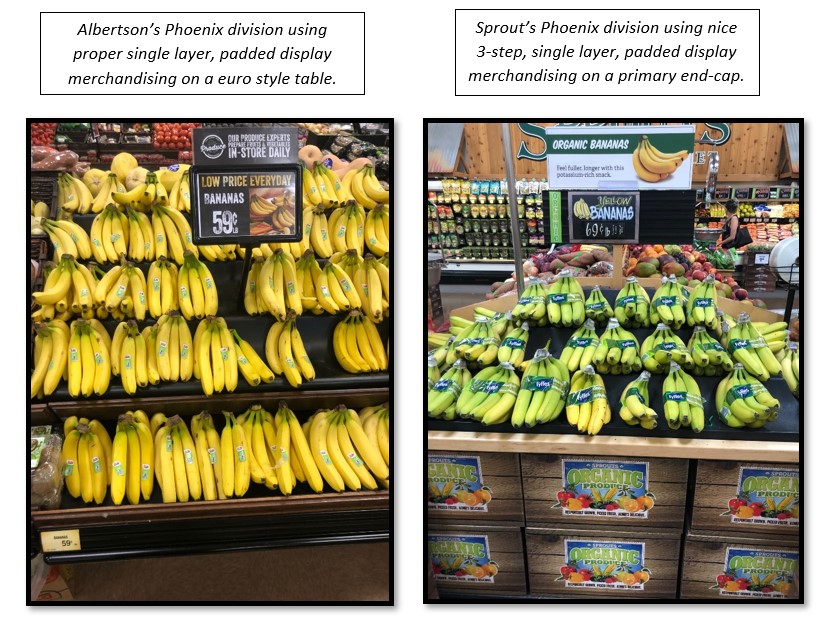

Bananas are a commodity that cannot be over-filled in the morning for the sake of not re-filling the remainder of the day. Bananas need to be displayed with a single-layer technique that allows the retailer to fill more often throughout the day. Modifying your merchandising procedures can help reduce damaged or scarred fruit on the shelf or on the customer's kitchen counter.

No need to complicate the standard operating procedure for merchandising bananas; just follow these three steps:

- Merchandise bananas one layer high for optimal conditions.

- Ensure product is facing forward, with the label exposed to the consumer.

- Rotate older product up to the front of the display where customers shop first. All newly stocked bananas should be placed towards the back of the display.

Over-ripe, scarred, and bruised bananas should always be culled from the fresh display. These minimal culls should run through your mark-down or re-purpose program. Never let a bad bunch of bananas give customers a negative impression of the entire display!

Take care of your top tonnage category!

Ugly banana displays not only drive down sales and profits, but they also impact future customer shopping habits. Bananas that over-ripen quickly on your customer's kitchen countertop will make that shopper think twice before purchasing again. Losing repeat customer business on bananas means that Mrs. Jones is going somewhere else to find her bananas … and maybe several other items … or her entire shopping list!

Think of the banana category as a customer's barometer for freshness in your department. Long-lasting, perfectly ripened, clean bananas will pay dividends at the end of the day. Do not forget to treat every bunch of bananas like a fragile dozen of fresh eggs! Single-layer merchandising, filled often throughout the day.

Scott Schuette is a produce retail veteran of more than 35 years and was most recently the vice president of produce and floral for Fresh Thyme Market. He has been named Produce Retailer of the Year and Specialty Food Retailer of the Year over the course of his decades of service to the fresh produce industry.