“We're kicking your load.” Delivering that message to a produce buyer is the toughest part of the job for quality assurance personnel.

Buyers don't like hearing this news any more than QA likes delivering it. When a produce load shows one or more issues that prevent acceptance, oftentimes it's the messenger – the quality inspector – who is then subjected to a barrage of questions:

“What? Are you sure? Impossible!...How bad is it? Did you take pictures?...Oh great, I've got 300 of those already sold for tonight.”

The shipper isn't thrilled with the news, either. Nobody wins when a produce load is rejected.

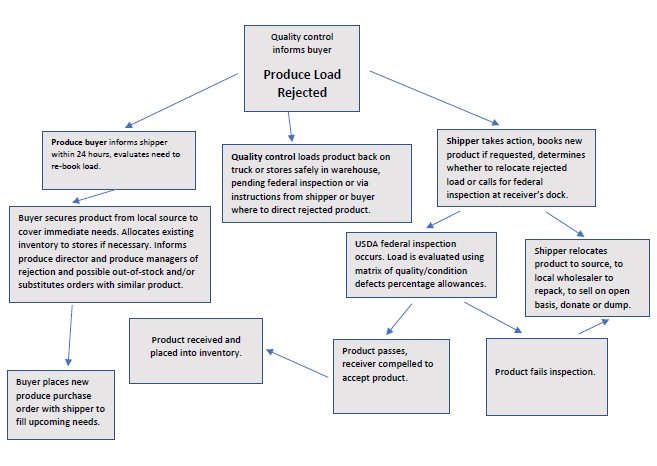

The buyer must scramble and make a series of calls to report and react to the rejection – and in some cases make sales allocations. The supplier or shipper must also react, rebooking product, making calls to their growers, sometimes coordinating a federal inspection with the buyer, and facing the loss of the product value and the loss of future purchase orders.

Rejected loads tie up valuable dock space, create added paperwork and make everyone's day and week longer than it needs to be.

Fresh produce is, on average, 90-plus percent water, and it is inherently volatile. It can develop issues during growth, harvest, storage, packing or shipping. Post-harvest, issues can include decay, temperature, damage, sizes, packs, grades, brands, varieties, brix, misrotation, dehydration and more.

A good produce delivery compares with a properly executed golf swing; with so many control points to consider, if you just focus on a few fundamentals, you can usually make things work out all right.

Here's a few thoughts on the sometimes sticky rejection scenario.

Rejection prevention

Be someone's customer

When you find a competitive shipper that you're comfortable with, one who provides not only consistent, quality produce but also keeps you informed on changing market conditions – that's the shipper you want in your corner. Be that shipper's customer and maintain a good relationship with them. This generally results in uninterrupted supply and minimal rejections.

Know your specs

When you ask for precise product specifications, there is less chance for rejection. For example, ensure that you're asking for a specific variety (regular parsley or flat leaf?), specific grade (No. 1 or No. 2 peppers?) and specific pack and size (volume fill or tray pack nectarines?). Your chain or organization may require multiple sizes, grades or varieties for the same load.

Confirm your order verbally and in writing to ensure there are no misunderstandings.

Ask for photos

The tight-market strawberries you finally found have “occasional” white shoulders? Get a good example photo before deciding.

Cantaloupe described as having a “nice straw color netting?” Grapefruit showing a little “sheepnose?” Tomatoes have any “catface” growth cracks? Blueberries are “diamonds?” Honeydew described as “eating like candy?” Ensure what's going to get loaded ahead of time.

Ask for photos, for samples, for brix readings and for other information so you know up front what to expect when the produce load arrives and whether it will be acceptable.

Ask for market conditions, price availability, trends. Is this the early, middle or end of a particular commodity deal? A good shipper-buyer relationship will result in the mention of any possible issues up front.

If the shipper says, “We're getting close to the end,” or “I'm not sure this is your quality spec,” believe them and consider loading elsewhere or not at all.

These are clues that may indicate that the product is not consistently arriving well. Explaining a product availability shortage is always better than trying to force the issue and loading questionable product.

Special handling needed

Many items need special handling or optional quality-assurance care steps to ensure good delivery.

These include things like Techtrol for strawberries, top ice for corn, broccoli or other select vegetables, fumigation, precooling, cross-contamination precautions such as properly loading conventional with organic items.

Any omission or failure to apply certain proactive steps could result in a rejection or product loss.

Post rejection

Maintaining a good supplier-buyer relationship

This isn't always easy, as rejections adversely stress even the best of relationships.

Keep in mind that you and your shipper are in it for the long haul and rejections happen even to the best shippers.

The shipper usually does everything possible to avoid a rejection. And when one occurs, the shipper usually does everything possible to mitigate the rejection. One example: replacing the product as soon as possible and getting to the source of the issue to minimize the chances of another rejection happening anytime soon.

The buyer can help the relationship by acknowledging the occasional rejection happens, staying pragmatic and taking steps to avoid further rejections with everything that he or she can control, relying on the best advice and data available.

“A little neglect may breed mischief; for want of a nail the shoe was lost; for want a horse the rider was lost; for want of the rider the battle was lost.” – Benjamin Franklin